- Home

-

About Us

About Us

PERRIER Bottling Machines is a family-owned company focused on innovation. We offer the best-in-class equipment with the lowest cost of ownership. We are resolved to maintain the technical leadership we have achieved over the years.

-

Machines

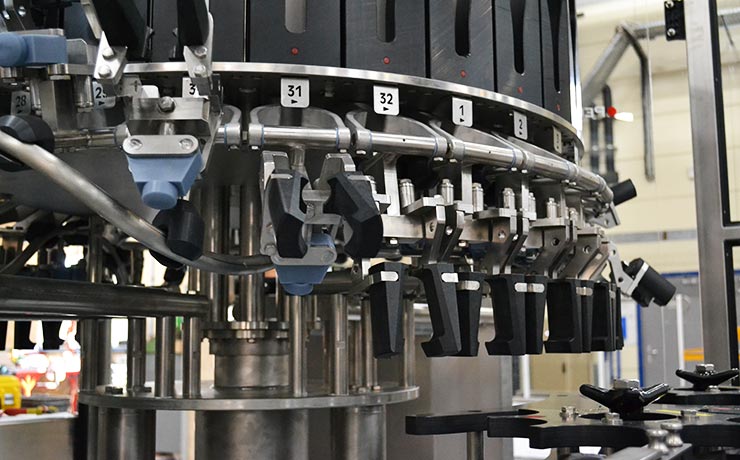

PERRIER Machines

Serving many different markets, PERRIER machines earned a stellar reputation and became business standards for quality, very high reliability & very lowest cost of ownership over their very long life cycles

-

Industry Sectors

Sectors We Serve

Over the last 50 years many Industries came to PERRIER for technical solutions and we have PERRIER equipment operating at diverse industries helping our customers achieve success in many countries of the world.

- Services

- Contact Us

- Careers